We provide a Ploughshare® Mixer and a laboratory mixer for servicing your mixing needs. Depending on your mixing requirements and the material attributes the mixer can be run under inert gas (nitrogen). Often our mixing services are executed as a further contract manufacturing step prior or after the milling of chemical products.

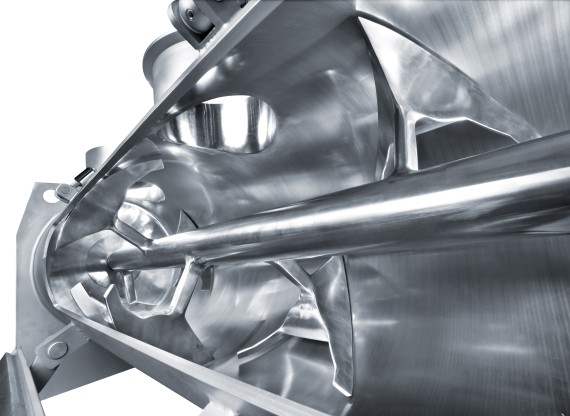

Ploughshare® Mixer

Features:

- Chopper units: The mixer consists of four shredders

- Equipment for liquid supply: The mixer has two nozzles for adding liquid components or for coating with oil

- We reach highest quality mixes on the mixing plant

- Reproducibility of the batches

- Gentle treatment of the product

- Easy accessibility to all inside parts of the mixer

Areas of application:

- Processing of bulk materials (powdery, granular, fibrous)

- Addition of liquids to dry solid materials (moistening, coating with oil)

- Addition of anti-caking agent

Laboratory Mixer (Ploughshare®-Mixer)

Features:

- The mixer has a total volume of 20 liters.

- Our Laboratory Mixer is a Ploughshare® Mixer, just without shredders or nozzles.

- The mixer is ideally suited for the product and process development.

- The front plate is swiveling.

- Stepless control of mixer shaft rotation speed

Areas of application:

The Laboratory Mixer is suitable for development and small-scale production for the following industries:

- Nutritional supplements

- Food additives

- Pharmaceutical industry

- Cosmetics

- Chemical industry

- Minerals

- Building Materials